So, What Is PEX?

PEX is the trade name for this Wham Bam developed build surface that is similar to PEI. PEX has a higher glass transition rate and higher melt point than PEI allowing you to print nearly any filament including resisting PETG from bonding too well with the build surface.

It has the least adhesion of the PC,PEI and PEX so it takes getting settings right and setting your gap right. Once you have done the setting perfectly, you will be rewarded with the BEST PRINTING EXPERIENCE ever. (Addify does not guarantee you will have the same feeling as we do, but it was heart melting for us when we tried this build plate) Wham Bam only uses authentic 3M brand high-temperature adhesive for guaranteed results.

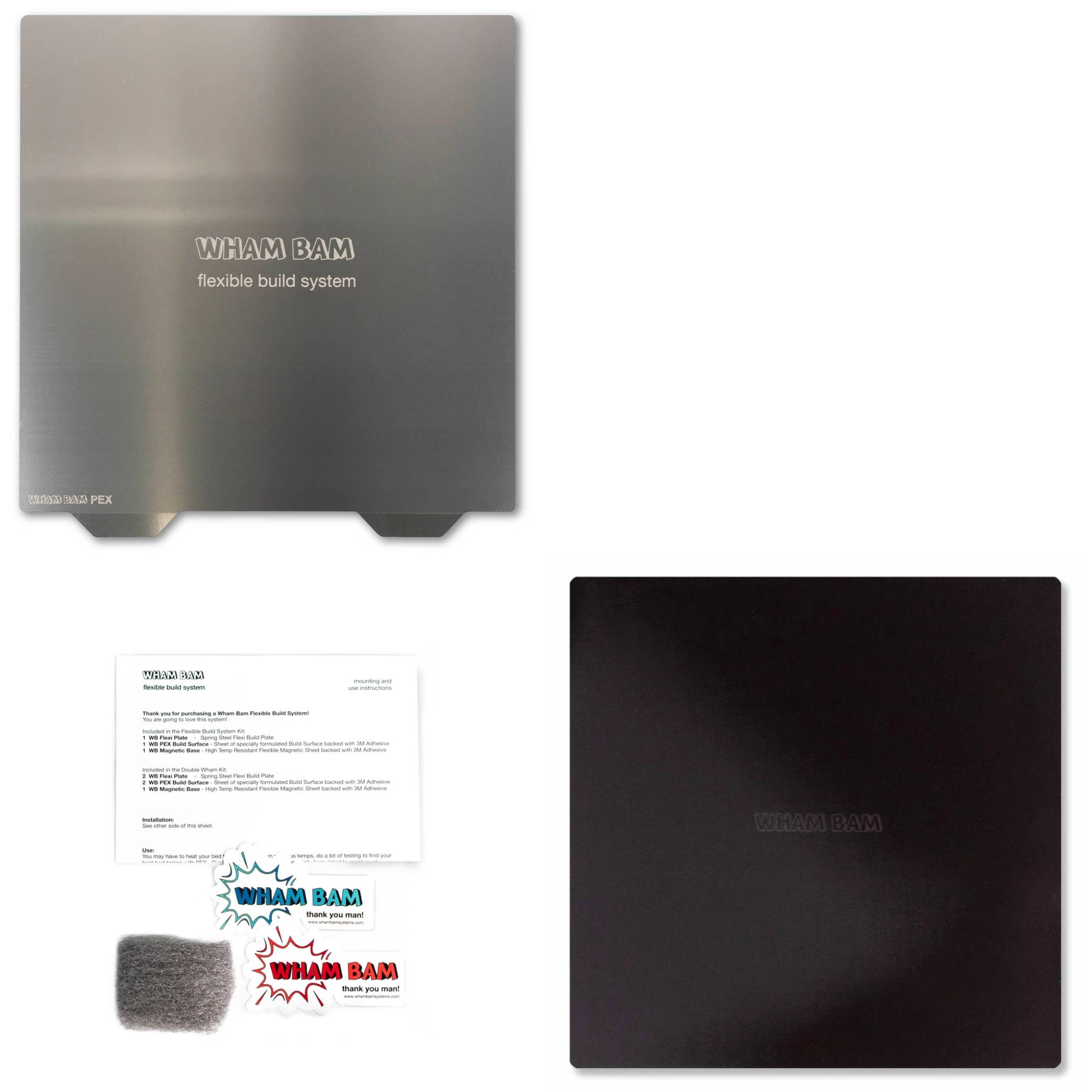

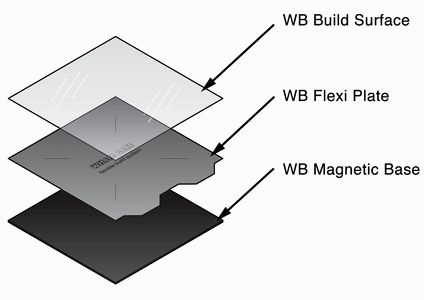

The Flexible Build System includes:

- 1x Wham Bam Flexi Magnetic Base (high temp-resistant up to 150 degrees with high temp 3M adhesive)

- 1x Wham Bam Flexi Build Plate (spring steel)

- 1x Wham Bam PEX Build Surface Custom Formulated PEX (with high temp 3M adhesive)

- 1x Steel Wool 000 (for prepping your PEX Build Surface)

PEX Build Surface

Wham Bam has developed the Wham Bam PEX Build Surface from a specially formulated polymer with a higher melt point than PEI that attracts most any filament without damaging the sheet. Prints easily pop off once cooled and flexed. Our PEX build surface is 0.4mm thick and pre-backed with 3M adhesive so it takes seconds to install.

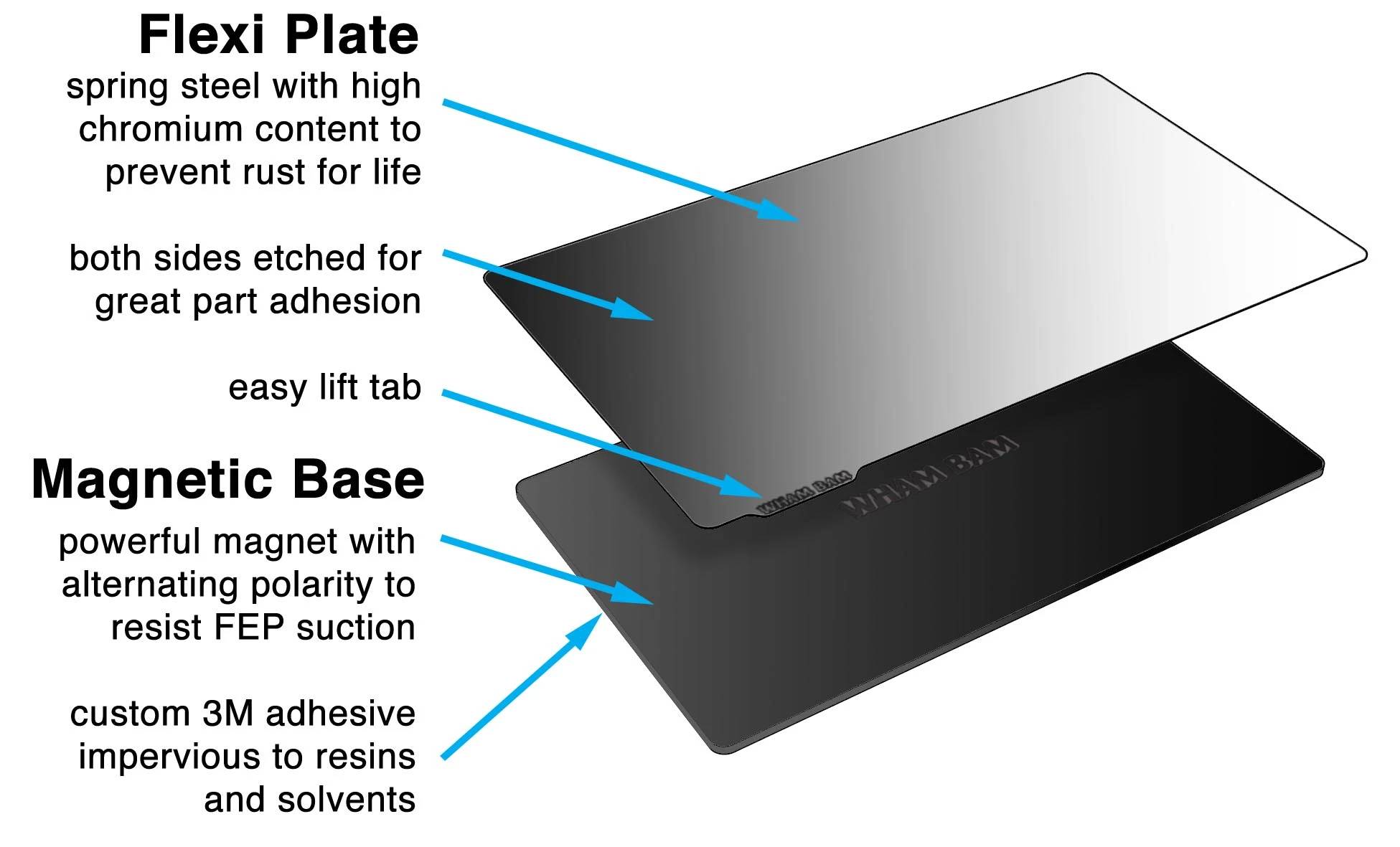

Flexi Plate

The Wham Bam Flexi Plate is made from high-quality flexible spring steel designed to be bent thousands of times without kinking. The spring alloy contains a high level of chromium to ensure no rust or oxidation for its lifetime. The Flexi Plate is 0.4mm thick. Build surface sold separately.

Magnetic Base

The Wham Bam Magnetic Base has been specially formulated to resist high temperatures for long periods of time, without any loss of performance. Guaranteed to resist heated beds up to 150°C continuously. They are 1mm thick and pre-backed with high-temperature 3M adhesive making installation a breeze!

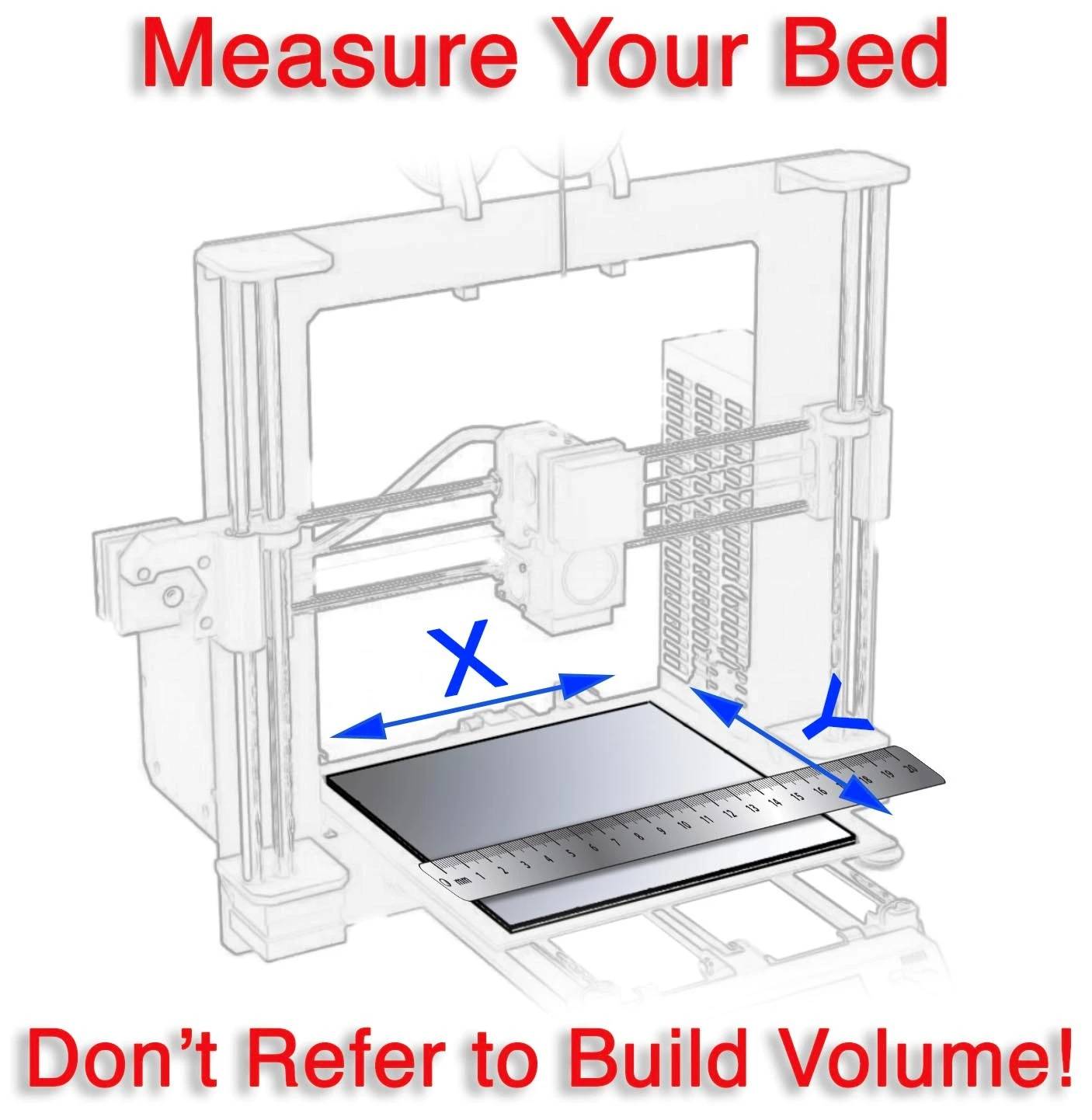

*Please confirm bed size on your actual machine prior to ordering. Addify and Wham Bam are not responsible for mistaken sizes ordered. See Wham Bam’s sizing guide here.

For more information on this product, click here to Wham Bam official website: Flexible Build System

繁體中文

繁體中文

Reviews

There are no reviews yet.